With all the hype today about new kinds of super smart software incorporating concepts such as the Internet of Things (IoT), artificial intelligence (AI) and machine learning, it is easy to forget about the critical role that actual hardware physical assets play in creating microgrids and other forms of distributed energy resources (DER) aggregation and optimization.

Without the generators, solar photovoltaics (PV) panels and energy storage devices that underpin any power supply option – not to mention ancillary infrastructure such as switchgear, distribution infrastructure and relays – there is no microgrid. While it is true that advances in software are enabling new use cases and can help squeeze more value out of physical assets, companies such as Encorp focus on the controls through an elegant hardware-based architecture that is robust and based on proven experience over the last 30 years of technology development.

When designing a microgrid or a virtual power plant, key questions arise that revolve around hardware provided by many manufacturing partners. Some of these partners may have their own software to help enable assets to function properly. Many DER assets themselves come with some set of controls.

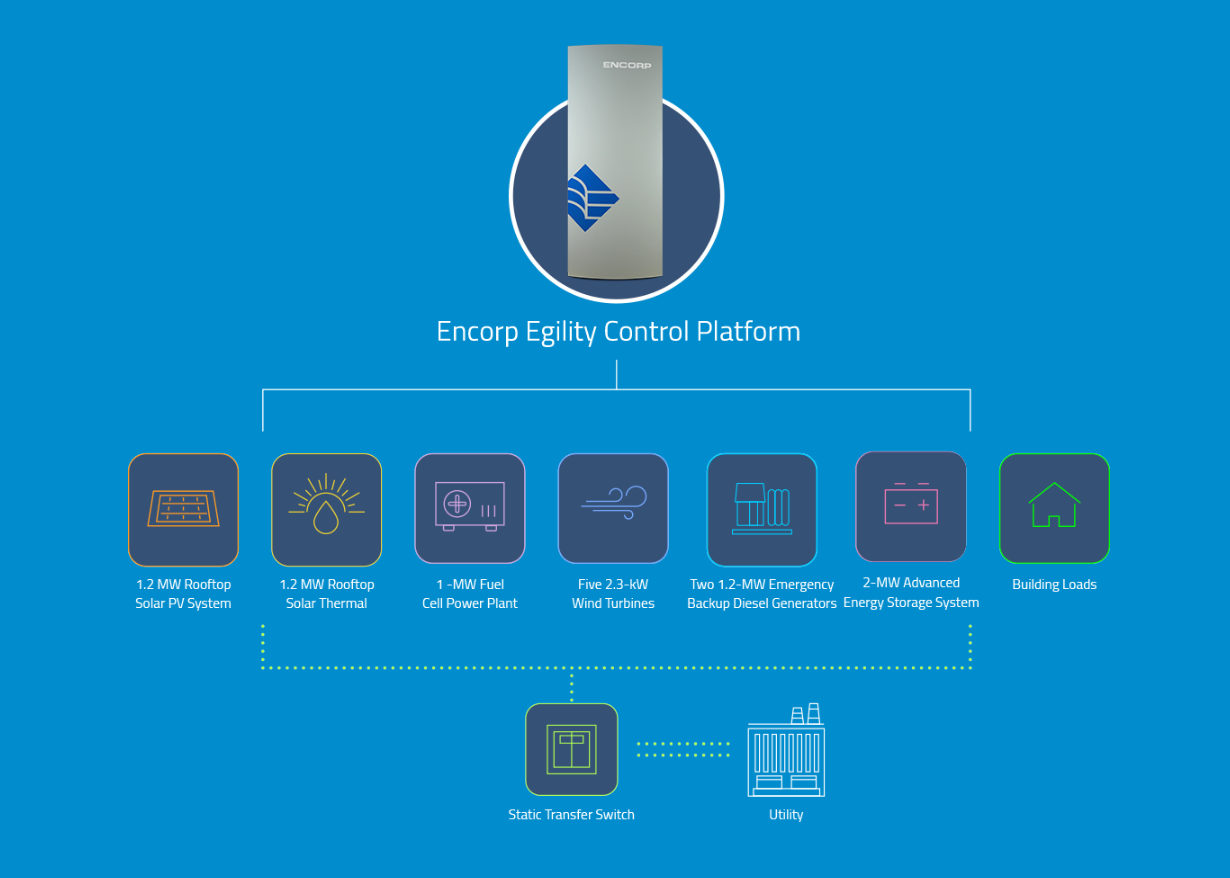

While these micro-controllers can optimize each individual asset, they still need a master set of controls to ensure the system is operating as efficient as possible. In essence, Encorp’s Egility controls platform is a controller controlling controllers. While this phrase is redundant, it captures what a microgrid is all about. Orchestrating a diverse pool of generation, storage and load assets in a way that enable any project’s goals to be met in a concrete and hard way. It is no accident that resilience is often described as “grid hardening.”

Hardware remains the backbone of any microgrid or other form of energy infrastructure project. Controls, incorporating software, can be viewed as a complex overlay that helps complex forms of optimization. Yet this software is only as a good as it is in managing and direction various hardware assets.

Most microgrids are retrofits. They therefore incorporate various vintages of technology, often from the same manufacturer. It is only through years of experience that engineers can design, install and then operate and maintain such diverse assets into a seamless and smoothly operating microgrid systems. In the past, integration was a major challenge for controls, since such hardware assets were not designed to necessarily be bundled together and operate as a system. The beauty of the learning curve is that it is ow recognized that microgrids can be evolutionary and controls can be upgraded incrementally as technology advances.

Common points of failure with microgrids include battery systems not quite ready for prime time, older generators that have not been properly maintained and software systems based on novel controls strategies but not fully vetted in real world operating environments. Other simmering debates in the microgrid controls space include whether it is better to offer a proprietary system or an offering that consists of off-the-shelf components.

Encorp has navigated through these changes over the last 30 years with a hybrid approach that leans on time tested engineering principles that value hardware, but which seeks to incorporate new software algorithms that boost value without comprising the integrity of the underlying hardware components.